Brick Masonry Definition

Brick masonry is a highly durable

form of construction. It is built by placing bricks in mortar in a systematic

manner to construct solid mass that withstand exerted loads. There are several

types of bricks and number of mortars which can

be used to construct brick masonry. The bond in brick masonry, which adheres

bricks together, is produced by filling joints between bricks with suitable

mortar. Special cautions shall be practiced while mortar is mixed and placed

since it greatly affect the performance and durability of masonry structure.

Types of Brick Masonry Work

1. Brick Work in Mud

•The mud is used to fill up various joints

brick masonry work.

•Thickness of the mortar joint is 12 mm.

•it is the cheapest type of brick masonry

•employed for construction of walls with

maximum height of 4m.

2. Brick Work in Cement

This type of brick masonry is

construction by laying bricks in cement mortar rather than mud which is used in

brick work in mud.

There are different types of brick

used in the construction of brick masonry which include:

1.Common Burnt Clay Bricks

2.Concrete Bricks

3.Sand Lime Bricks (Calcium Silicate

Bricks)

4.Fly ash Clay Bricks

5.Engineering Bricks

6.Other Brick Types include

bullnose, channel, coping, cownose

and

hollow bricks.

Materials and Equipment Used in Brick Masonry Construction

•Mortar Mix or Mason Mix Bricks

•Tape measure

• hammer

•Hose, level, or theodolite

•Trowel Level

•Wheelbarrow

•Goggles

•Jointer

• And other equipment according to

project ans

personal preferences

Brick Masonry Construction Preparations

1.Check the level of the ground

using level, theodolite or transparent hose level.

2.Set the layout of the structure.

3.Trace of building axis and wall

alignment using gypsum powder, chalk, or similar, marking the trenches for

foundation.

4.After that,install

foundation wall, cure foundation for minimum two days before beginning of brick

masonry construction.

5.Distribute bricks in several

stacks along project site to cut time and effort later.

6.Wet bricks few hours prior to the

work. Not only does this avoid absorbing too much water from mortar but

also improve adherence of bricks and mortar.

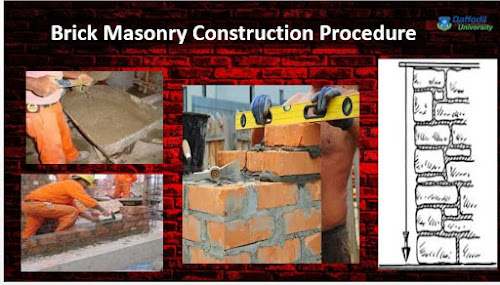

Brick Masonry Construction Procedure

1.Initially,

mix the mortar with water and blend it until a smooth and plastic mortar is produced

2.After that, place the mortar on

foundation line evenly using trowel (25mm thickness and one brick wide is

recommended for laid mortar).

3.Then, lay the first course of

stretcher bricks in the mortar. Start with second brick, apply mortar to the

head joint end of each brick, After that shove the bricks into place firmly so

that the mortar is squeezed out of all side of the joints.

4.Utilize

a level to examine the course for correct height. ensure that bricks are plumb

and level.

5.Place another mortar line

alongside the first course, then begin laying the second course.

6.Use the two half bricks to begin

the second to ensure that the first two courses are staggered for structural

purposes.

7.To finish the second course of the

lead, lay three header bricks and make sure that they are plumb and level.

8.The

third and fifth courses consists of stretchers similar to the first course. The

fourth course begins with single header, followed by stretchers. Use the level

to make sure that the lead is true on each course. Lastly, this pattern of

brick laying is used till the target height is reached

Points Considered in Supervising Brick Masonry Constructions

The

following points should be observed in the construction of brick masonry:

•Use good quality bricks.

•Ensure that brick courses are perfectly horizontal.

•Verticality of the wall should be ensured by frequently checking with

plumb-bob.

•Whenever work is stopped brick masonry should be left with toothed end.

•Use of brick bats should be avoided.

•Raising walls by more than 1.5 m in one day shall be prevented.

•Raise face joints to a depth of 12 to 20mm so as to be used as a key

for plastering or pointing.

•Brick masonry should be regularly cured for 2 weeks.

•The thickness of mortar joints shall be 10 mm both horizontally and

vertically.

No comments